ROTANA Tools

We are able to design tools in such a way that they fit your concrete needs. With regard to a particular way of machining and based on specification of a given workpiece, we design and produce a unique tool with all required functionalities.

Ultrahard Tools

Tools with ultrahard cutting edges made of materials such as diamond and cubic boron nitride allow for an application of completely new cutting strategies which result in increased machining productivity, improved quality of machined surfaces, reduction of necessary production steps and enormous increase to tool life.

The complexity of the production chain gives us an ability to optimize and more importantly control the technological process from the first concept to the final product.

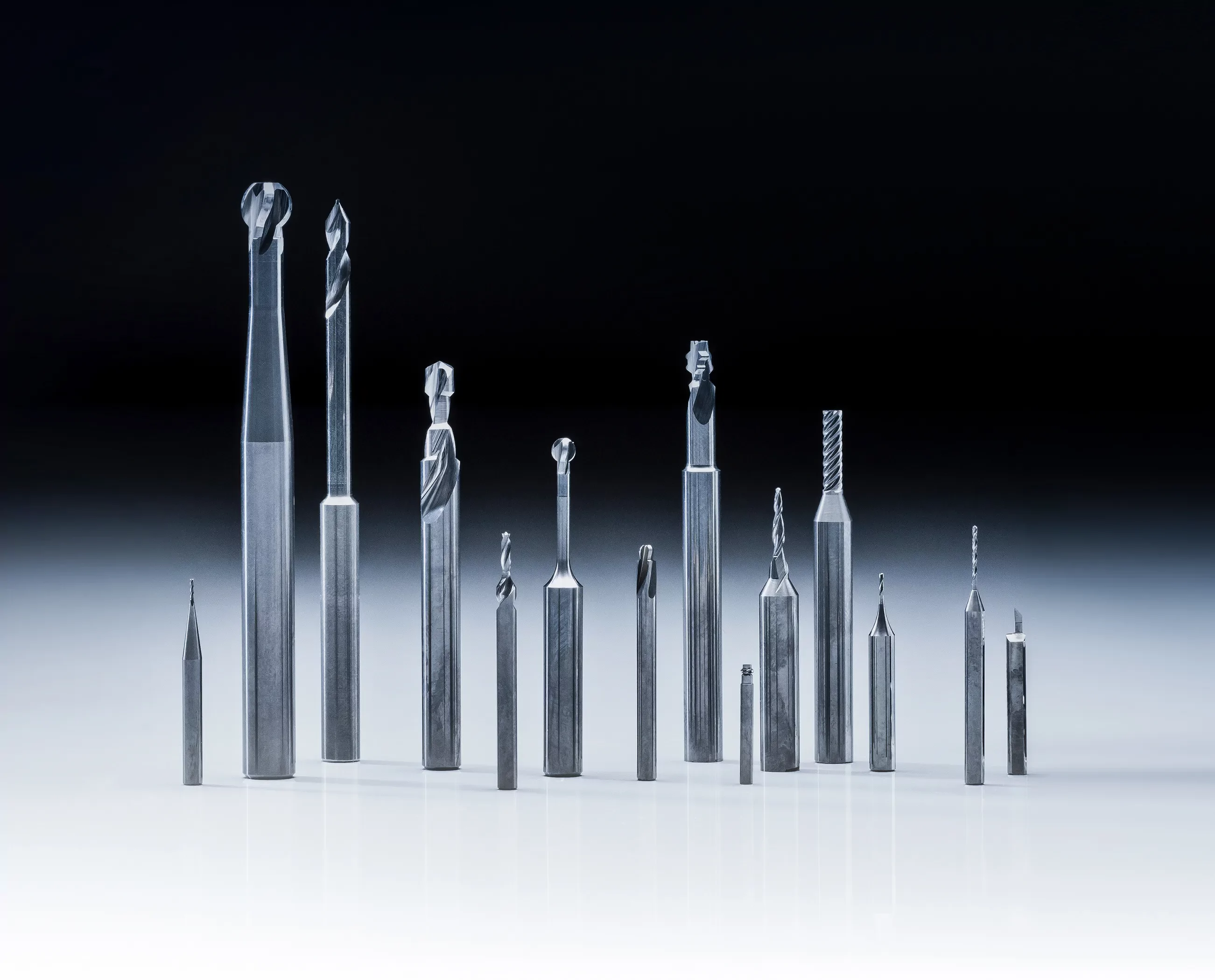

Microtools

We will tailor our microtools to fit your specific requests. Thanks to our close cooperation during the conception phase, implementation and following optimization process, we are able to produce a tool that will ideally fit your tightly set production processes.

Our modifications include microtools of diameters 0,1-3 mm with different top geometry, used especially for milling, bore machining and turning with a precision of ± 1 μm.

Bore Machining

Our solid carbide tools with well-chosen coatings, right geometry and correct design will allow you to machine bores in various materials with high efficiency and keep high quality of machined surfaces.

Each of our design tools answers with its functionalities some specific requirement of a machined surface. While designing tools for next steps, we put high emphasis on their production sequence in such a way so that they are always perfectly functional in the range of given requirements.

Milling Tools

In ROTANA Plc. we produce monolithic endmills made of solid carbide. Our tools can machine both standard and special materials, such as super alloys (Inconel, Hastelloy, Nimonic etc.), titan alloys, Al and Cu alloys, graphite or even composite materials.

There are many factors entering the machining process together with specific requests on a given tool that affect the resulting quality. And it is precisely by the right choice of functionalities for a milling tool that it is possible to compensate for these factors to some degree and thus improve the machining process itself.

Stationary Tools

Our company can tailor a resulting tool according to its intended application considering both its layout and its functionality. The biggest advantage of such a solution is an impressive array of possible final shapes reflecting uniqueness of a workpiece .

Simultaneously we can incorporate during the designing phase an exchangable insert from a standard programme of other renowned tool producers. The following modification to a special insert allows us to offer our customers a fully-fledged solution in a short period of time.